PRESS RELEASE 03/2024

Ferroplan

Release date: 07.03.2024

Ferroplan expands its operations into Swedish markets

Ferroplan announces its expansion into Swedish conveyor markets as part of its strategic growth plan to grow an international presence.

With a solid foundation in the Finnish market, Ferroplan is excited to extend its reach into Sweden. This strategic move reflects company’s commitment to providing innovative conveyor solutions to customers in the wider Nordic region.

To lead its expansion into the Swedish market, Ferroplan has appointed Andreas Niska as the dedicated salesperson for Sweden. With his expertise and knowledge of the mechanical forest and sawmill industry, Niska will focus on building strong relationships with customers and meeting their specific needs.

“The companies in Sweden represent a robust and dynamic market with significant growth potential,” says Niska, and continues, “Ferroplan recognizes the immense potential of the Swedish market and aims to capitalize on this opportunity by leveraging its expertise in providing specialized conveyor solutions. By offering innovative, reliable, and cost-effective solutions, Ferroplan is well-positioned to meet the evolving demands of Swedish forestry and sawmill companies.”

Ferroplan has gained a significant success in Finland by offering specialized conveyor solutions for over 40 years. These solutions have been instrumental in ensuring smooth and reliable material flow within customer operations, and they have expressed satisfaction with their investments in Ferroplan’s products.

“We are thrilled to embark on this new chapter of growth as we expand into the Swedish market. With our proven track record of delivering specialized conveyor solutions and exceptional service, we are confident that we can meet the customer needs and further develop our position in Sweden”, says Antti Rousku, CEO of Ferroplan.

Ferroplan looks forward to serving the Swedish market with the same dedication and commitment to excellence that has distinguished it in Finland for over four decades.

###

For more information:

Antti Rousku, CEO, Ferroplan, tel. +358 40 683 1360, antti.rousku@ferroplan.fi

Andreas Niska, Sales Manager Sweden, tel. +46 702544860, andreas.niska@ferroplan.fi

About Ferroplan:

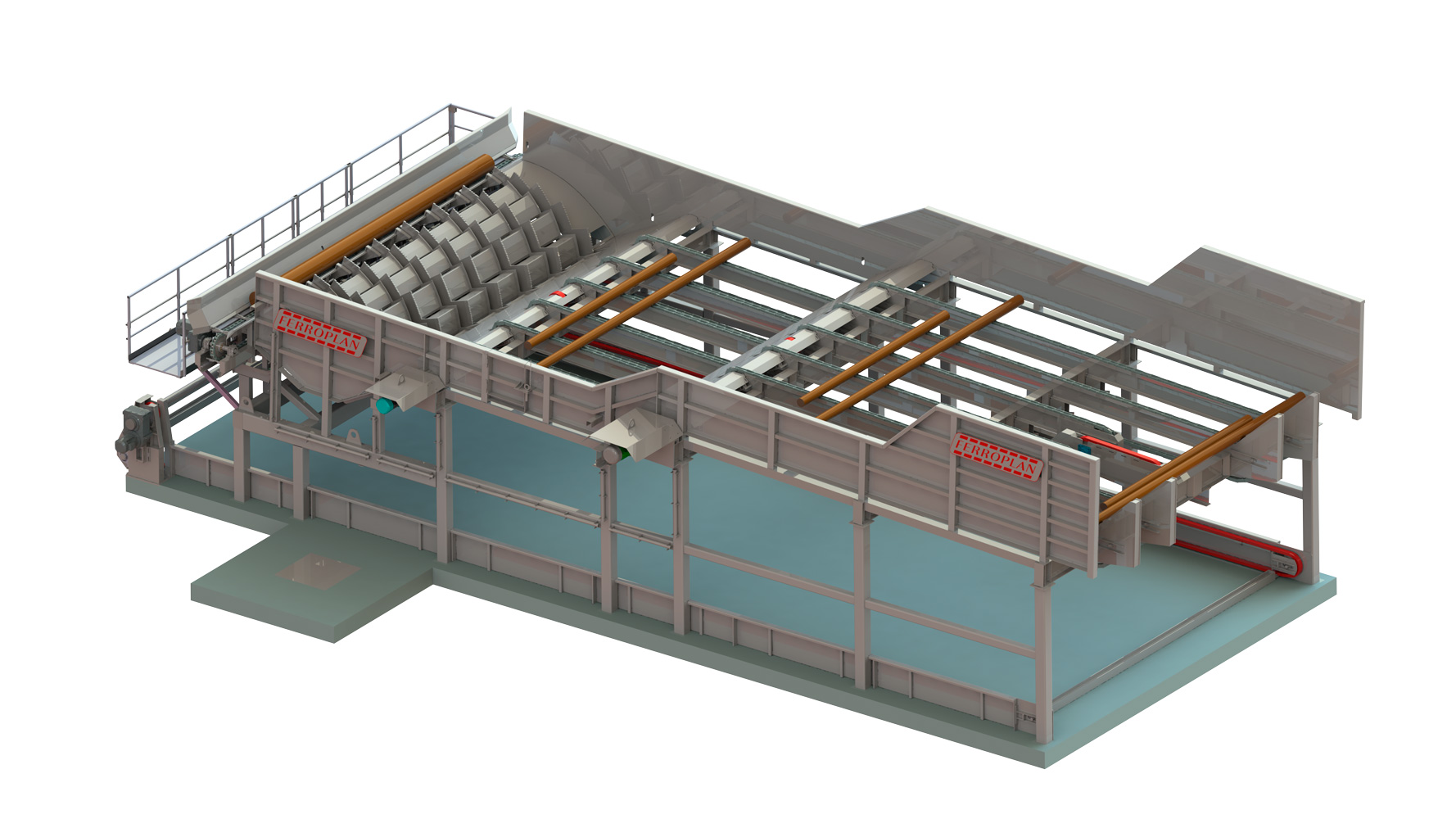

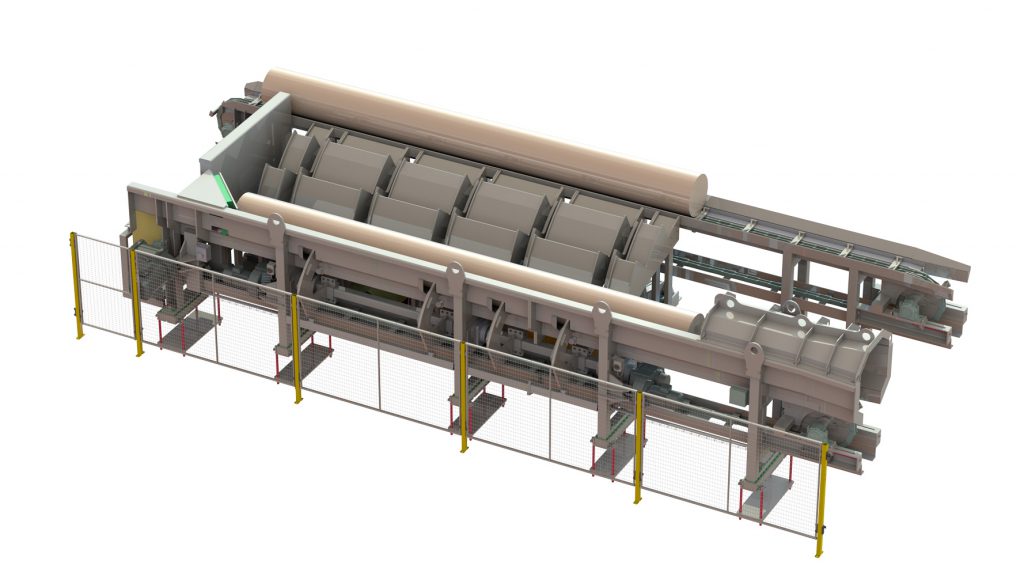

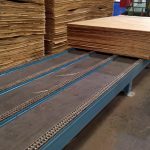

Ferroplan is Finland’s leading company that designs, manufactures, and maintains conveyor solutions. Manufacturing facilities of Ferroplan are located in Orimattila, Finland and Jelgava, Latvia. Conveyors are a vital part of operational efficiency, and Ferroplan’s solutions automate and optimize the flow of materials in production facilities, ensuring continuous production. Ferroplan’s commitment to its customers’ success is also evident in services and maintenance. Ferro Care provides reliable spare parts and maintenance services, while tailoring maintenance agreements to the customer’s needs. Follow us on LinkedIn or visit our website www.ferroplan.fi